Ask any project manager, IT engineer or site director what their biggest pain point is when setting up a new site or operation, and you’ll hear it loud and clear:

Connectivity.

It’s always the same story:

“Waiting on fibre.”

“Delayed by the cable guys.”

“Running lines through the mud.”

“Cost us thousands to connect that gate.”

Despite all our advances in technology, many UK operations are still chained to the idea that high-performance networking means laying physical cable. And that cable takes time, money, effort — and, often, permits and trenches.

But what if you could skip all of that?

What if your network didn’t rely on digging, trenching or booking Openreach weeks in advance?

You can.

And it’s already happening.

Wireless mesh networking is replacing cable and fibre in more UK deployments every month. And once teams switch — they rarely go back.

In this post, we’ll explore the real costs of cabling, the advantages of going mesh, and why more organisations are cutting the cord.

The True Cost of Cabling

On the surface, running cable doesn’t sound too bad. Just dig a trench, pull some cable, get it terminated and connected — job done, right?

Not quite.

Here’s what that really looks like in the UK:

-

Permit delays

Need to dig near a road? Cross a footpath? You’re into council permit territory — and that means waiting. -

Cost overruns

Trenching, ducting, and fibre install costs can spiral quickly. And if you’re only doing it for a few months of use? It’s a sunk cost. -

Damage risk

Sites change fast. Cabling gets cut, flooded, frozen or accidentally dug up — especially when works evolve over time. -

Lack of flexibility

Need to move a site cabin? Add a security camera? You’re either running new cable or going without. -

Downtime

If a cable fails, it often means manual intervention, especially in remote or unmanned areas.

And that’s just for the physical setup. What about remote sites, moving vehicles, mobile teams?

For modern deployments — fibre simply isn’t fit for purpose.

How Wireless Mesh Replaces Fibre

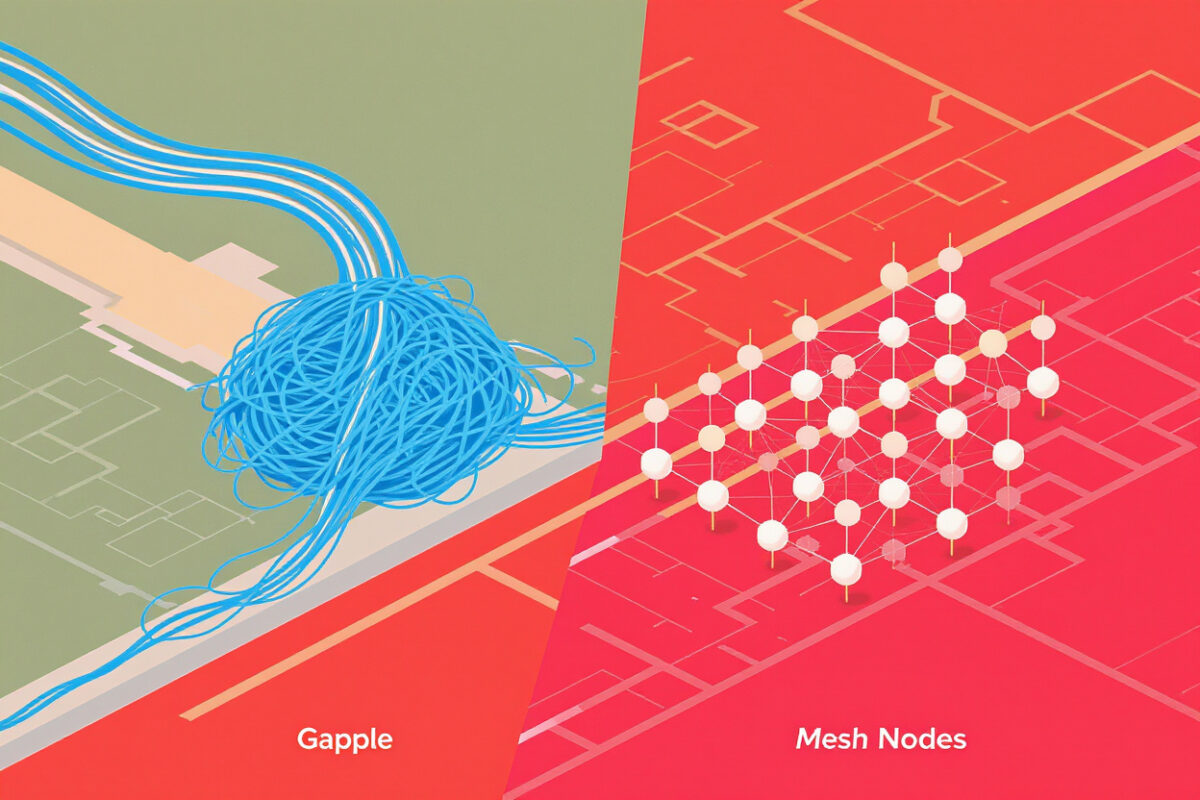

Wireless mesh networking offers a totally different model.

No trenching. No cabling. No fixed line install.

You simply deploy rugged wireless nodes across your site — attach cameras, turnstiles, access points, radios or sensors — and let the mesh do the rest.

Each node communicates with the others, forming a self-configuring, self-healing wireless network.

Here’s what you get instead of cable:

-

Rapid deployment — same-day network rollout

-

True mobility — nodes can move as your site evolves

-

Instant redundancy — built-in failover via multiple paths

-

No external contractors — in-house install and control

-

Remote management — monitor, update, diagnose from anywhere

You’re not waiting for someone to dig a trench. You’re not calling Openreach. You’re not held hostage by geography.

You’re in control.

The Use Cases Where Mesh Wins — Hands Down

Let’s run through some of the real-world scenarios where we’ve seen UK clients ditch fibre for mesh:

New Build Construction Sites

Multiple cabins, cranes and security towers across a muddy field — zero infrastructure. With mesh, teams deploy a working network on day one. No digging, no waiting.

Temporary Events and Festivals

Imagine trying to lay cable across 40 acres of event ground. Mesh links ticket booths, lighting rigs, backstage areas and safety staff — all without a single trench.

Ports and Transport Yards

Dynamic environments with moving vehicles, containers and mobile teams. Cable can’t adapt. Mesh can.

Remote Utility Sites

You can’t run cable across a moor or up a water tower. With solar-backed mesh nodes, you don’t need to.

High-Security Environments

Secure perimeters and smart access gates often need rapid deployment and secure comms. Mesh delivers encrypted, self-contained networks fast.

But What About Speed and Reliability?

We hear this a lot.

“Is mesh really as fast and reliable as fibre?”

Short answer: in most use cases — yes.

Modern industrial-grade mesh networks are:

-

Low latency

-

High bandwidth (up to 1Gbps)

-

Encrypted end-to-end

-

Resilient to failure (self-healing paths)

For surveillance footage, access control, voice traffic, sensor data, or even general internet access — mesh performs beautifully.

No, it won’t replace high-speed fibre in a data centre.

But on a construction site? Port? Rail yard? Field event?

It’ll outperform fibre every time — because it actually works there.

The Flexibility to Grow, Move, and React

This is where mesh really shines.

Add a new CCTV camera?

Plug it into a nearby node — it’s live in minutes.

Moving your site cabins next month?

Lift the mesh units with them — no network redesign.

Adding turnstiles at a temporary gate?

Mount a node, connect, go.

You’re not calling a contractor. You’re not recabling. You’re not waiting a week.

Mesh gives you the agility that wired networks simply can’t.

And in a world where plans change by the day — that agility is everything.

Real Talk: What Mesh Doesn’t Do

Let’s be clear — mesh isn’t magic.

It needs line-of-sight for best performance. It needs mounting points and power. It needs someone to plan the layout.

But compared to fibre?

The barriers are lower. The speed is faster. The headaches are fewer.

And crucially — you own the infrastructure.

Once deployed, mesh can move to your next job, your next event, your next site.

You’re not paying for a trench you’ll never use again.

Conclusion

Cables had their place. But that place is shrinking.

In 2025, more organisations are waking up to the true cost of wired connectivity — and turning to wireless mesh to break free.

It’s faster to deploy. Easier to manage. More resilient, more flexible, and more cost-effective across dozens of real-world use cases.

So if you’re still planning fibre runs across your next site…

Ask yourself:

Do I really need to dig? Or is it time to cut the cord?